-

-

Call Now +91 9833287656

Pipe Fittings Manufacturer

Pipe fittings, also known as pipe connectors, attach one pipe to another in order to lengthen the run or change the flow direction in a plumbing system. These are used to combine, divert or reduce the flow of the water supply, and they come in a variety of sizes to fit the pipe they will connect.

Types of pipe fittings

Elbow

The production of elbows takes place both with cold forming and hot forming in the Hiton Fittings plant. All our elbows are produced in accordance with quality and current technical standards (ASTM / ASME / ANSI) and are available in a wide range of thicknesses, grades and sizes (from ½” to 56″).

- From : 90° Elbow, 45° Elbow, 180° Return, Reducing Elbow, Mitered Elbow

- Type : Seamless / Welded / Fabricated

- Size : 1/8” NB TO 48” NB.

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

Tee

Our Tees are produced by cold and hot forming, in accordance with current technical standards (ASTM / ASME / ANSI) and applying rigorous quality controls and available in a wide range of thicknesses, grades and sizes (from ½” to 56″).

- From : Straight, Reducing, Cross

- Type : Seamless / Welded / Fabricated

- Size : 1/8” NB TO 48” NB.

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

Reducer

Our Reducers are produced by cold and hot forming, in accordance with current technical standards (ASTM / ASME / ANSI) and applying rigorous quality controls and available in a wide range of thicknesses, grades and sizes (from ½” to 56″).

- From : Concentric, Eccentric

- Type : Seamless / Welded / Fabricated

- Size : 1/8” NB TO 48” NB.

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

Lateral

Our Lateral are produced by cold and hot forming, in accordance with current technical standards (ASTM / ASME / ANSI) and applying rigorous quality controls and available in a wide range of thicknesses, grades and sizes (from ½” to 56″).

- From : 45° angle, 90° angle

- Type : Seamless / Welded / Fabricated

- Size : 1/8” NB TO 48” NB.

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

Cap

Our Caps are produced by cold and hot forming, in accordance with current technical standards (ASTM / ASME / ANSI) and applying rigorous quality controls and available in a wide range of thicknesses, grades and sizes (from ½” to 56″).

- From : Pipe Cap, End Cap

- Type : Seamless / Welded / Fabricated

- Size : 1/8” NB TO 48” NB.

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

Stub End

Our Stub Ends are produced by cold and hot forming, in accordance with current technical standards (ASTM / ASME / ANSI) and applying rigorous quality controls and available in a wide range of thicknesses, grades and sizes (from ½” to 56″).

- From : Long, Short, Lap Joint

- Type : Seamless / Welded / Fabricated

- Size : 1/8” NB TO 48” NB.

- Thickness : Sch 5s, Sch 10s, Sch 40s, Sch 80s, Sch 160s, Sch XXS

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A403 / A234 / A420 / B366

- Dimension : ASME/ANSI B16.9, ASME B16.28, MSS-SP-43 etc.

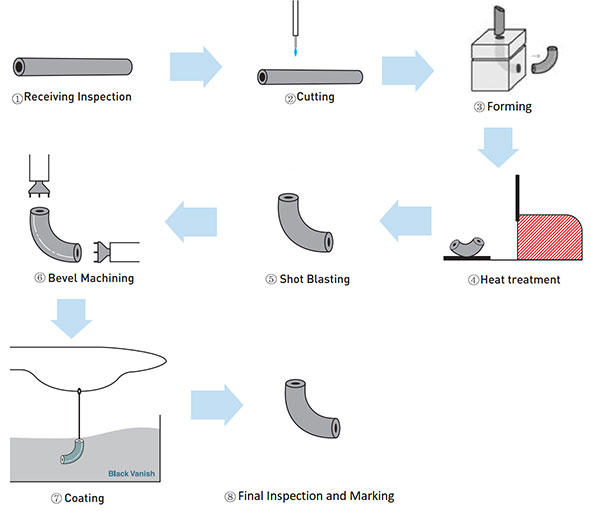

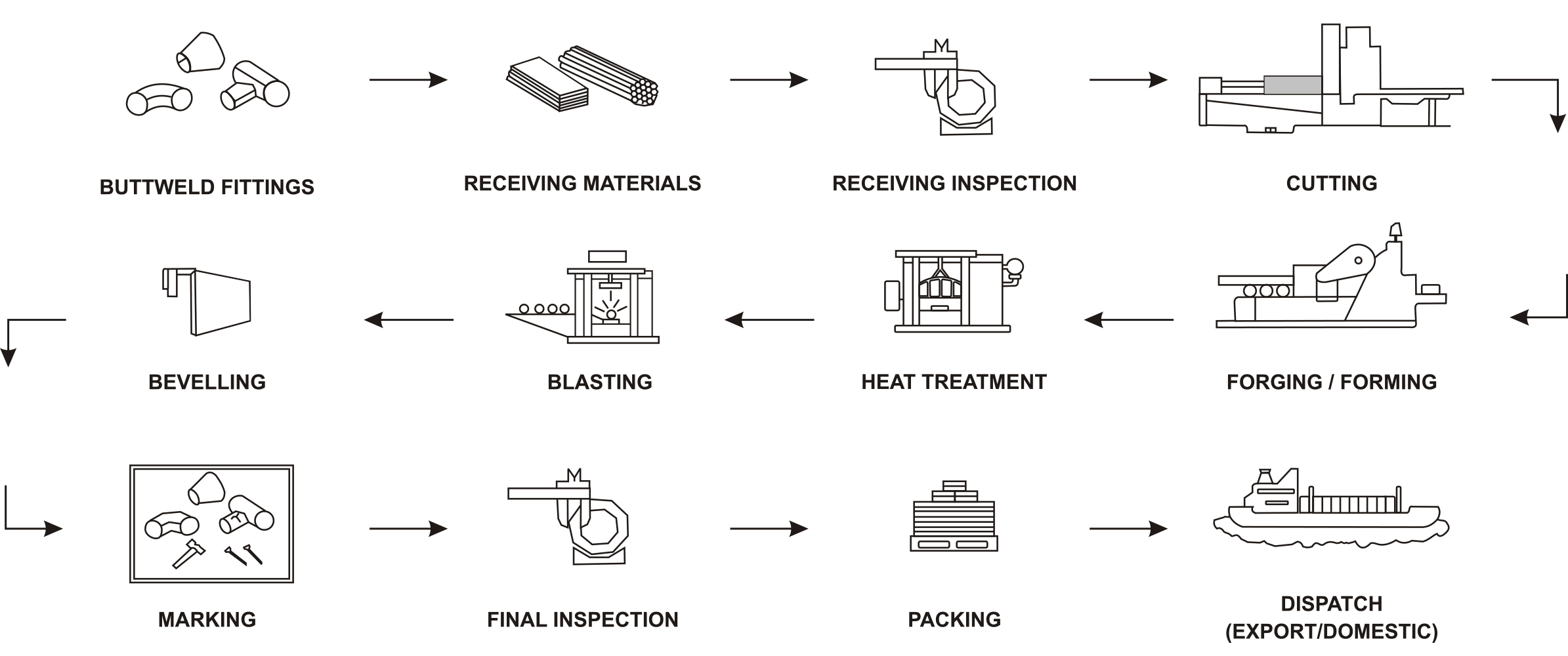

Manufacturing Process

To manufacture wrought Elbow various methods are used, these are the some types of Hot forming and cold forming processes :

-

-

Mandrel Method(Hot Forming) :

One of the most common Pipe Fittings Manufacturing Process for manufacturing Elbows from the pipe is a mandrel method which is a kind of hot forming method.Extrusion method (Cold Forming) : In the cold extrusion method, a pipe with the same diameter as a finished product is pushed through a die and formed into its desired shape.

"UO" Method (Welding) : UO method is used to manufacture the medium size of the elbow, tee, and reducers. The plate is cut out into a specially designed shape, it is formed first into a U-shape using a die and then into an O-shape or tubular form using another die, that is why this method is known as UO method.

Hot Forming Die Bending Method : In a Hot Forming Die Bending method, a Pipe is heated to forming temperature & formed in the die with the specific shape, this process may be repeated as needed to obtain the required shape, size, and wall thickness.

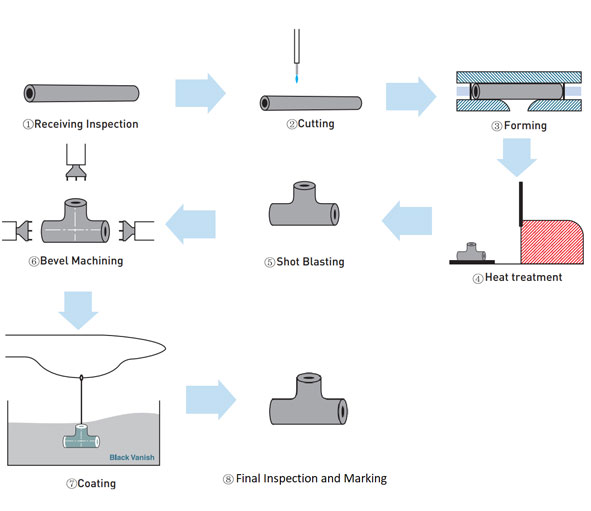

To manufacture wrought Tee various methods are used, these are the some types of Hot forming and cold forming processes :

-

-

Hydraulic Bulge Method (Cold Forming) :

The hydraulic Bulge method is used to manufacture Tee. Cut piece of Pipe is placed in hydraulic die and liquid is fill inside the pipe, Hydraulic pressure pushes out the branch, in the fixed opening in the die. This method gives a good surface finish. However, higher thickness Tee cannot be manufactured by this method."Monaka" Method : One of the most used methods for manufacturing Elbows from plates. After two pieces of raw material plates are cut out symmetrically, each piece are press formed and welded together, which somewhat reminds us of the Japanese delicacy, "Monaka."

Hot Extrusion Method : Tee with large diameters, heavy wall thickness, and /or special material with challenging workability that cannot be manufactured using the hydraulic bulge method are manufactured using hot Extrusion Method.

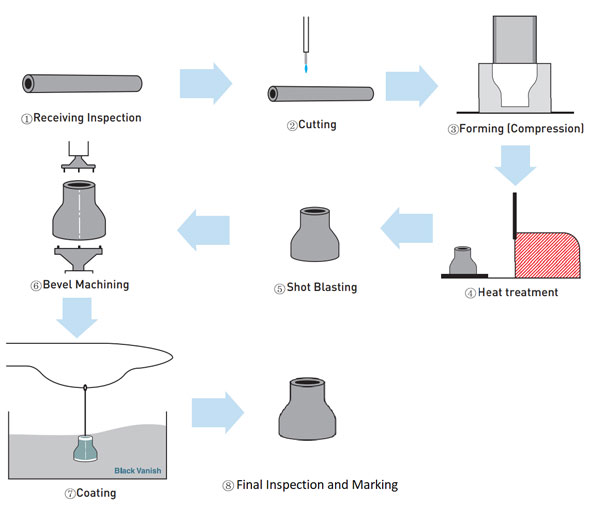

To manufacture wrought Reducer various methods are used, these are the some types of Hot forming and cold forming processes :

-

-

Outer Die Method :

Most common method for manufacturing Reducers is Outer Die method. The pipe is cut and pressed in the outer die; compressing the one end of the pipe into a smaller size. This method is useful for manufacturing of small to medium size of reducers."Plate Forming Method : Plates can also be used to manufacture Reducers. In an UO method, plate is cut in a specially designed shape which is formed into an U-shape and an O-shape respectively, then finished with a single weld seam. The "Monaka" method is also available and is similar to that of Elbows and Tees, using two symmetrically cut plates formed and welded together with two seams. Both methods are used for large diameter items.

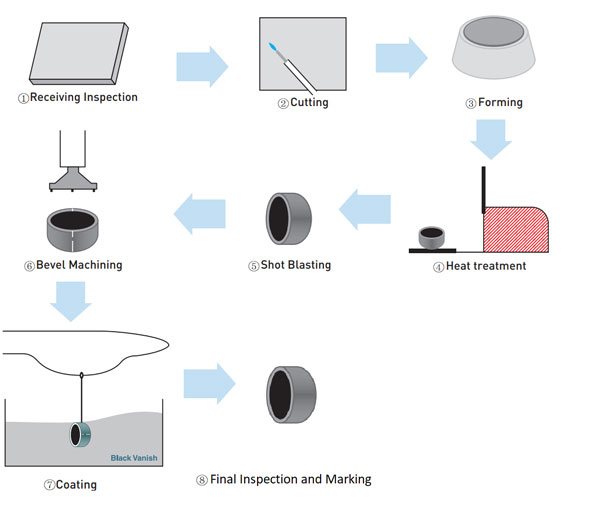

To manufacture wrought Cap various methods are used, these are the some types of Hot forming and cold forming processes :

-

-

Deep Drawing method :

Caps are manufactured by the Deep Drawing method. In this method, Plate is cut out in a circle and formed by deep-drawing die.

To manufacture wrought Stub End various methods are used, these are the some types of Hot forming and cold forming processes :

-

Flaring method :

Stub Ends or Lap Joints Flange are manufactured by flaring method. The pipe end is a flare or spared out to from a flange face. Stub ends are also manufactured by forging in which forge block is machined to final dimension.

we are the manufacturers in the various Materials

-

Stainless Steel

ASTM A403 WP 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L

Heat Treatment Explore More -

Carbon Steel

ASTM A234, ASME SA234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70, ASTM A420 WPL3, A420 WPL6.

Heat Treatment Explore More -

Alloy Steel

ASTM A234, ASME SA234 WP1 / WP5 / WP9 / WP11 / WP22 / WP91

Heat Treatment Explore More -

Duplex & Super Duplex Steel

ASTM A815, ASME SA815 UNS S31803, S32205, 2205, UNS S32750, S32760, S32950, 2507

Heat Treatment Explore More -

High Nickel Alloy

Nickel 200, 201, Monel 400, K500, Incoloy 800, 825, Inconel 600, 601, 625, Hastelloy C276, C22, Alloy 20, Titanium (Grade 2 & 5), Cupro-Nickel 70/30, 90/10.

Heat Treatment Explore More