-

-

Call Now +91 9833287656

Flanges Manufacturer

A Flange connects piping and components in a piping system by use of bolted connections and gaskets. Most commonly used flanges are weld neck flange, slip on flange, blind flange, socket weld flange, threaded flange and lap joint flange (RTJ Flange). This type of connection in a flange allows for ease of disassembly and separation for repair and regular maintenance. Most common specification for carbon steel and stainless steel flange is ANSI B16.5 / ASME B16.5.

Types of Flanges

SORF

SORF Flanges are a popular type of pipe flange designed to accept pipe into the bore/center of the flange for welding around both the Outer Diameter (OD) of the pipe and on the interior side of the connection. The slip-on flange is a simple and excellent alternative to a weld neck as it does not have a weld bevel, and therefore allows the pipe to be adjusted in length relative to its position of the flange. The bore of the slip on will give ample amount of space for the matching pipe. This allows for enough working space for the welder and fabricator to make the connection.

- Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Size : ½" (15 NB) to 48" (1200NB)

- Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A182 / A105 / A350 / B564

- Dimension : ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278

WNRF

WNRF Flanges are the most popular flange type with a neck extension with a weld bevel at the end. This type of flange is designed to butt weld directly to pipe to provide a superior and relatively natural form connection. In larger sizes and higher pressure classes, this is almost exclusively the type of flange connection utilized. If only one bored flange style existed in modern applications, the weld neck would be your flange of choice.

- Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Size : ½" (15 NB) to 48" (1200NB)

- Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A182 / A105 / A350 / B564

- Dimension : ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278

BLRF

A BLRF Flange is a solid steel piece with no bore (interior diameter) and primarily designed to cap off a line. As the majority of flange connections allow for the passing through of air or fluid via an interior opening, blinds give the ends of pipe connections a well formed termination point or rerouting of the media in question towards another portion of the pipe assembly. Opt for a blind flange in these cases, as well as in instances when a pipe line requires a future modification such as the installation of a valve or fitting to reroute flow.

- Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Size : ½" (15 NB) to 48" (1200NB)

- Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A182 / A105 / A350 / B564

- Dimension : ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278

SWRF

SWRF Flanges are a less common but equally effective connection for flanges which require less overall available space than a traditional weld neck flange, with a counterbore in the center to allow for a clean weld of pipe into the socket. Usually furnished in smaller nominal pipe sizes, these make an excellent alternative to weld necks and slip ons when necessary. An assembly with limited space may be an instance in which a socket weld is selected, provided the pressure class is comparatively low and the fluid is not corrosive or for extremely high temperature service.

- Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Size : ½" (15 NB) to 48" (1200NB)

- Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A182 / A105 / A350 / B564

- Dimension : ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278

Special Flanges

Except the most used standard flanges, there are still a number of special flanges such as:

- Orifice Flanges

- Long Welding Neck Flanges

- Weldoflange / Nipoflange

- Expander Flange

- Reducing Flange

- Flange Face Type : Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

- Size : ½" (15 NB) to 48" (1200NB)

- Class : 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

- Standard : ANSI, ASME, BS, DIN, JIS, EN

- Specification : ASTM A182 / A105 / A350 / B564

- Dimension : ANSI B16.5, ANSI B16.47, ANSI B16.36, ANSI B16.48, BS 4504, EN1092, UNI 2277/2278

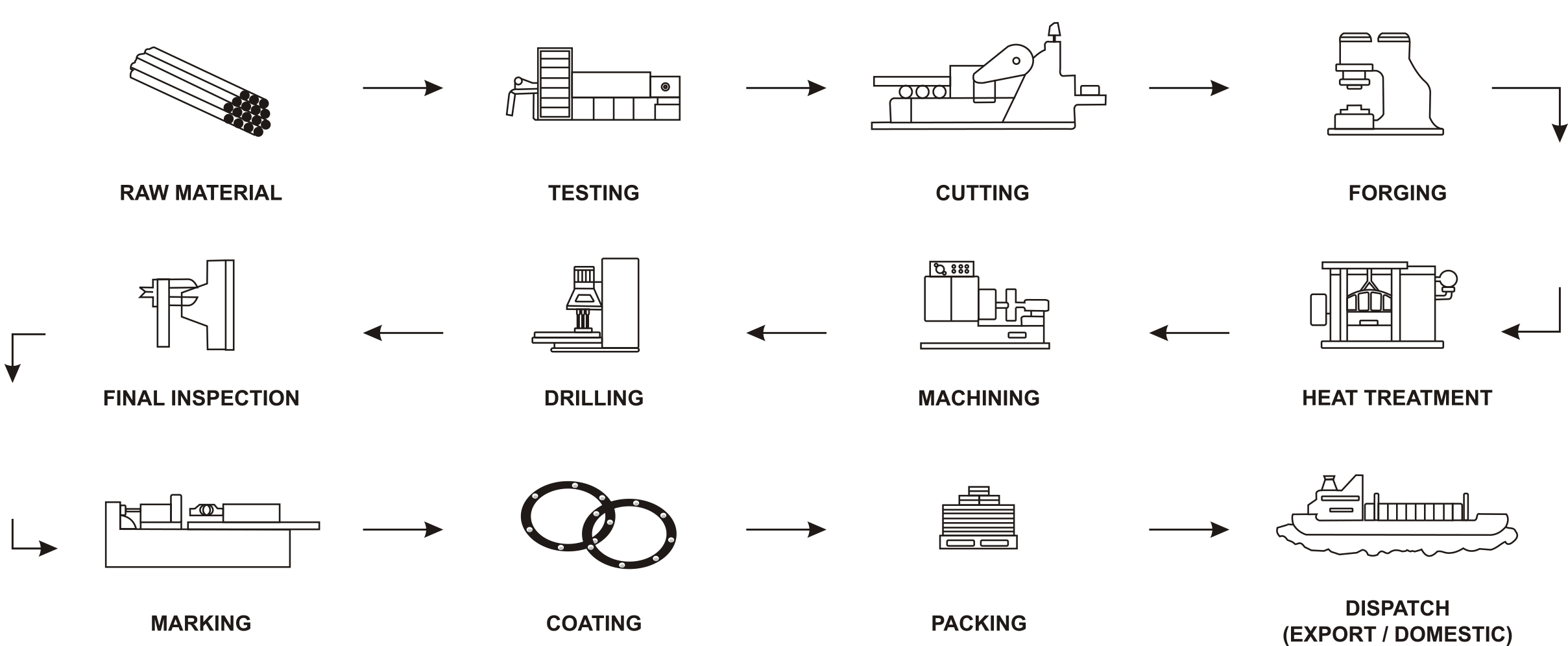

Manufacturing Process

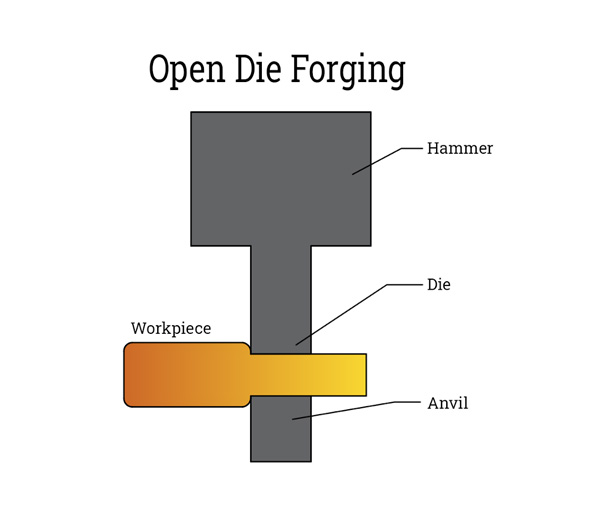

Open die forging is a type of forging in which the metal pieces or workpiece are deformed to the desired shape with the help of dies that do not completely enclose the material.

-

-

Open die forging is the process of deforming a piece of metal between multiple dies that do not completely enclose the material. The metal is altered as the dies “hammer” or “stamp” the material through a series of movements until the desired shape is achieved. Products formed through open forging often need secondary machining and refining to achieve the tolerances required for the finished specifications. Open die forging is often used for short run forgings of parts that are simple, rather than complex, in design, such as discs, rings, sleeves, cylinders and shafts.

Custom shapes can also be produced with open die forging. The repeated working of the material through the deformation process increases the strength of the grain structure. Some additional benefits of open die forging include improved fatigue resistance and strength. Open die forging also reduces voids.

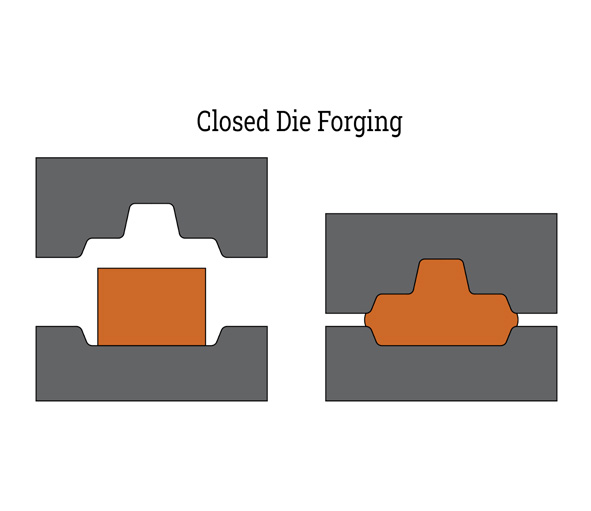

Closed die forging, also known as impression forging, is a process where two halves of a die move toward each other to enclose the workpiece or billet.

-

-

Closed die forging (also referred to as impression die forging) is a metal deformation process that uses pressure to compress a piece of metal to fill an enclosed die impression. In some closed die forging processes, a succession of impression dies are used to modify the shape of the material into the final desired shape and form. The type of material, tightness of tolerances, and need for heat treatment can determine the number of passes the product requires through the dies.

Two Equipment types used for closed die forging:

Mechanical forging presses: Manufacturers use mechanical presses for high volume product runs.

Hydraulic forging presses: These presses are useful for more complex shapes.

Drop forging: This process is economical for large runs and is often used instead of casting because of its superior internal grain structure.

we are the manufacturers in the various Materials

-

Stainless Steel

ASTM A182 304, 304L, 304H, 309, 310, 310S, 316, 316L, 317, 317L, 321, 321H, 347, 347H, 446, 904L

Heat Treatment Explore More -

Carbon Steel

ASTM A105, ASTM A350 (LF1, LF2, LF3), ASTM A694 (Gr. F42, F46, F56, F52, F60, F65, F70).

Heat Treatment Explore More -

Alloy Steel

ASTM A182 Gr. F5, F9, F11, F12, F22, F91

Heat Treatment Explore More -

Duplex & Super Duplex Steel

ASTM A182 Gr. F51, F52, F53, F54, F55, F57, F59, F60, F61, UNS S31803, S32205, S32760, S32750

Heat Treatment Explore More -

High Nickel Alloy

Nickel 200, 201, Monel 400, K500, Incoloy 800, 825, Inconel 600, 601, 625, Hastelloy C276, C22, Alloy 20, Titanium (Grade 2 & 5), Cupro-Nickel 70/30, 90/10.

Heat Treatment Explore More